- Full 0 … 100 %RH measurement, temperature range up to +180 °C (+356 °F) depending on model

- Pressure tolerance up to 100 bar depending on model

- 4th generation Vaisala HUMICAP sensor for superior accuracy and stability

- Corrosion-resistant IP65/IP66 housing

- Excellent performance in harsh conditions; good chemical tolerance

- Traceable calibration for measurement and analog outputs (certificates included)

- 10-year warranty when annually calibrated at the Vaisala Service Center

Dpstar is a leading supplier of environmental measurement sensors for temperature, relative humidity, pressure, dew point, CO2 and other environmental condition monitoring for industrial process application and research. Since the ’90s, we earned a reputation as a trusted partner to our clients through our commitment and dedication. We are an authorized distributor and supplier of measuring sensors solutions from renowned manufacturers Vaisala. Vaisala is a global leader in environmental and industrial measurement. Building on 80 years of experience, Vaisala provides observations for a better world. Vaisala is a reliable partner for customers around the world, offering a comprehensive range of innovative observation and measurement products and services.

Vaisala HMT330 Series HUMICAP Humidity and Temperature Transmitters are designed for demanding industrial applications where stable measurements and extensive customization are essential. With multiple options to choose from, the instrument can be tailored to meet the specific needs of each individual application and is pre-configured for each delivery.

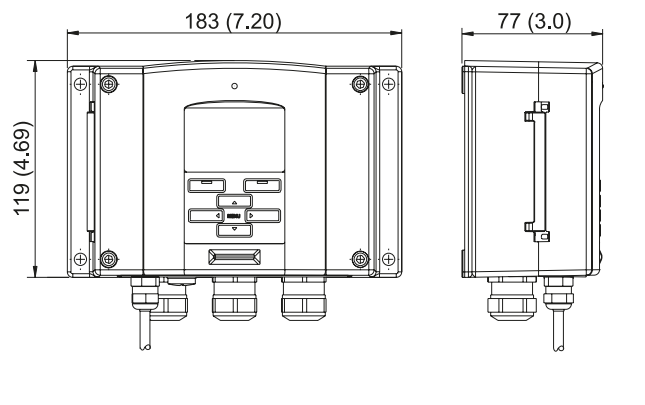

Dimension

Benefits

Proven Vaisala HUMICAP Performance

The HMT330 series incorporates Vaisala’s 40 years of experience in industrial humidity measurement. The updated fourth-generation HUMICAP sensor provides accurate and stable measurement even in environments with high humidity or chemical contaminants.

Wide Range Of Installation Options

The wide variety of measurement probes, several installation accessories, and universal mains and DC power options make the instruments easy to install in various locations and kinds of environments; walls, poles, pipelines, and ducts, for example. The input/output cable can be fed through the back of the transmitter, which is a useful feature, especially for cleanroom installations.

The HMT330 series includes six models:

- HMT331 for wall-mounted applications

- HMT333 for ducts and tight spaces

- HMT334 for high-pressure and vacuum applications

- HMT335 for high-temperature applications

- HMT337 for high-humidity applications

- HMT338 for pressurized pipelines

With multiple options to choose from, including local display, the HMT330 series can be tailored to meet the specific needs of each individual application and is preconfigured for each delivery. Also, the HUMICAPâ sensor itself can be selected according to specific measurement application needs.

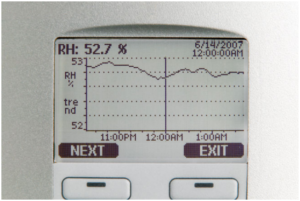

Graphical Display Of Measurement Data & Trends For Convenient Operation

The HMT330 series features an optional numerical and graphical display with a multilingual menu and keypad. It allows users to easily monitor operational data, measurement trends, and access measurement history of up to 4 years.

The display shows measurement trends and over four years of real-time measurement history. The display alarm allows any measured parameter to be tracked, with freely configurable low and high limits.

Versatile Outputs & Data Collection

The HMT330 can support up to three analog outputs; an isolated galvanic power supply and up to four relay outputs are also available. For serial interface, the USB service cable, RS-232, and RS-485/422 can be used. HMT330 is also capable of applying the Modbus communication protocol and,

together with an appropriate connection option, provides either Modbus RTU (RS-485) or Modbus TCP/IP (Ethernet) communication. The data logger, with real-time clock and battery backup, guarantees reliable logging of measurement data for over four years. The recorded data can be viewed on the local display or transferred to a PC with Microsoft Windowsâ software. The transmitter can also be connected to a network with an optional LAN interface, which enables an Ethernet connection. A USB service cable makes it easy to connect the HMT330 to a PC via the service port.

Flexible Calibration

HMT330 instruments are calibrated at five humidity points at the factory and come with a calibration certificate that meets all the relevant traceability and compliance requirements. A quick, one-point field calibration can be performed with the handheld HM70 meter. A two-point field calibration can

be performed, for example, with the HMK15 salt bath calibrator in a controlled environment. The transmitter can also be sent to Vaisala for recalibration, and accredited ISO/IEC 17025 calibrations and special calibrations are available.

Chemical Purge Minimizes Effects Of Contaminant

In environments with high concentrations of chemicals and cleaning agents, the chemical purge option helps to maintain measurement accuracy between calibration intervals. The chemical purge involves heating the sensor to remove harmful chemicals. The function can be initiated manually or programmed to occur at set intervals.

| Model | HMT331 | HMT333 | HMT334 | HMT335 | HMT337 | HMT338 |

| For | Measurement within rooms |

General purposes | High pressure and vacuum applications |

High temperatures | High humidity applications |

Pressurized pipelines |

| Temperature measurement range |

−40 … +60 °C (−40 … +140 °F) |

−40 … +80 °C (−40 … +176 °F) or −40 … +120 °C (−40 … +248 °F) |

−70 … +180 °C (−94 … +356 °F) |

−70 … +180 °C (−94 … +356 °F) |

−70 … +180 °C (−94 … +356 °F) |

−70 … +180 °C (−94 … +356 °F) |

| Operating pressure | 0 … 10 MPa (0 … 100 bar) |

0 … 1 MPa (0 … 10 bar) |

0 … 4MPa (0 … 40 bar) |

|||

| Measurement Performance | |

| Relative Humidity | |

| Measurement range | 0 … 100 %RH |

| Accuracy 1) 2) | |

| at +15 … +25 °C (59 … +77 °F) | ±1 %RH (0 … 90 %) |

| ±1.7 %RH (90 … 100 %RH) | |

| at −20 … +40 °C (−4 … +104 °F) | ±(1.0 + 0.008 × reading) %RH |

| at −40 … +180 °C (−40 … +356 °F) | ±(1.5 + 0.015 × reading) %RH |

| Factory calibration uncertainty 3) (+20 °C) |

±0.6 %RH (0 … 40 %RH) ±1.0 %RH (40 … 97 %RH) |

| Humidity sensor types | HUMICAP 180 HUMICAP 180C HUMICAP 180R HUMICAP 180RC HUMICAP 180VC |

| Response time (90 %) with HUMICAP 180 or 180C sensor at +20 °C (+68 °F) in still air | |

| with grid filter with grid + steel netting filter with sintered filter |

8 s 20 s 40 s |

| Response time (90 %) with HUMICAP 180R, 180RC, or 180VC sensor at +20 °C (+68 °F) in 0.1 m/s air flow | |

| with grid filter with grid + steel netting filter with sintered filter |

17 s 50 s 60 s |

| Temperature | |

| Accuracy at +20 °C (+68 °F) | ± 0.2 °C (± 0.36 °F) |

| Operating Environment | |

| Operating Temperature | |

| Probe with cable | Same as measurement range |

| Transmitter body, no display | −40 … +60 °C (−40 … 140 °F) |

| Transmitter body with display | 0 … +60 °C (32 … 140 °F) |

| Storage temperature | −55 … +80 °C (−67 … 176°F) |

| Compliance | |

| EMC compatibility | IEC / EN / BS EN 61326 1, industrial environment Note: Transmitter with display test impedance of 40 is used in IEC / EN / BS EN 61000-4-5 (surge immunity) |

| Compliance marks | CE, RCM, WEEE |

| Mechanical specifications | |

| Cable bushing | M20 × 1.5 for cable diameter 8 … 11 mm (0.31 … 0.43 in) |

| Conduit fitting | 1/2″ NPT |

| User cable connector (optional) | M12 8-pin male |

| Option 1 | Female plug with 5 m (16.4 ft) black cable |

| Option 2 | Female plug with screw terminals |

| Housing material | G-AlSi 10 Mg (DIN1725) |

| IP rating | IP66 IP65 (NEMA4X) with local display |

| Weight | 1.0 … 3.0 kg (2.2 … 6.6 lb) depending on selected model and options |

| Standard probe cable lengths | 2 m, 5 m, or 10 m (6.6 ft, 16 ft, or 33 ft) (Additional lengths available, see order forms for details) |

| Probe Cable Diameter | |

| HMT333 (+80 °C (+176 °F)) | 6.0 mm (0.24 in) |

| Other probes | 5.5 mm (0.22 in) |

| Inputs and Outputs | |

| Operating voltage | 10 … 35 VDC, 24 VAC ±20% |

| With optional power supply module | 100 … 240 VAC, 50/60 HZ |

| Power consumption at +20 °C (Uin 24 VDC) | |

| RS-232 | Max. 25 mA |

| Uout 2 × 0 … 1 V/0 … 5 V/0 … 10 V | Max. 25 mA |

| Iout 2 × 0 … 20 mA | Max. 60 mA |

| Display and backlight | + 20 mA |

| During chemical purge | Max. 110 mA |

| During probe heating (HMT337) | + 120 mA |

| Analog outputs (2 standard, 3rd optional) | |

| Current output | 0 … 20 mA, 4 … 20 mA |

| Voltage output | 0 … 1 V, 0 … 5 V, 0 … 10 V |

| Accuracy of analog outputs at +20 °C | ±0.05% full scale |

| Temperature dependence of the analog outputs | ±0.005%/°C full scale |

| External Loads | |

| Current outputs | RL < 500 |

| 0 … 1 V output | RL > 2 k |

| 0 … 5 V and 0 … 10 V outputs | RL > 10 k |

| Max. wire size | 0.5 mm2 (AWG 20) |

| Stranded wires recommended | |

| Digital outputs | RS-232, RS-485 (optional) |

| Protocols | ASCII commands, Modbus RTU |

| Service connection | RS-232, USB |

| Relay outputs (optional) | 0.5 A, 250 VAC |

| Ethernet interface (optional) | |

| Supported standards | 10BASE-T, 100BASE-TX |

| Connector | 8P8C (RJ45) |

| IPv4 address assignment | DHCP (automatic), static |

| Protocols | Telnet, Modbus TCP/IP |

| Optional data logger with real-time clock | |

| Logged parameters | Max. four with trend/min./max. values |

| Logging interval | 10 seconds (fixed) |

| Max. logging period with max. temporal resolution | 4 years, 5 months |

| Logged points | 13.7 million points per parameter |

| Battery lifetime | Min. 5 years |

| Display | LCD with backlight, graphical trend display of any parameter |

| Menu languages | English, Chinese, Finnish, French, German, Japanese, Russian, Spanish, Swedish |